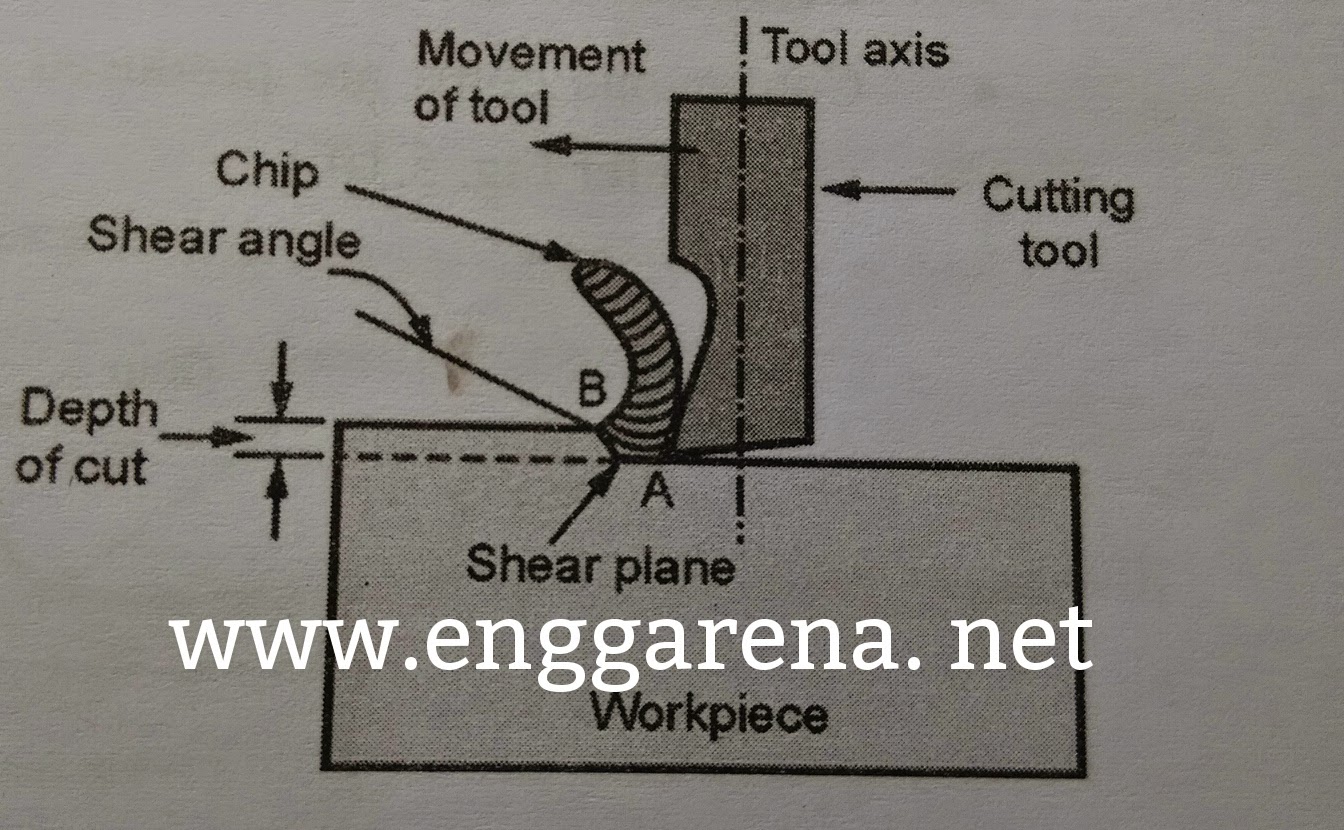

Any type of cutting process involves the tool, workpiece, chips, and of course, cutting fluids. Mechanics of metal cutting is the process of metal cutting in which various observations are made according to different parameters.

|

| Mechanics of Metal Cutting |

Table of Contents

Mechanics of Metal Cutting

For removing the metal from the workpiece, a wedge-shaped tool is constrained to move relative to the workpiece so that it can remove the metal in the form of chips.

During any cutting action the following observations are made:

- The removed material/metal is in the form of continuous chips or discontinuous chips.

- Thickness of the chip is more than the depth to cut.

- The hardness of the chip is also greater than the hardness of the base metal.

- There is no metal flow in the normal direction of chip flow.

- The chips are formed due to the process of deformation or plastic flow of material, which takes place by a phenomenon called slip.

- Flow lines are observed on the side and back of a chip which indicates that cutting involves a shearing mechanism.

- Because of the friction between the tool and the workpiece, a large amount of heat is generated. This large amount of heat can be reduced by having a sharp cutting edge and better tool finish, increased speed and improved tool geometry, use of best-cutting fluids and much more.

This comment has been removed by the author.

My brother recommended I might like this blog.

He was entirely right. This submit truly made my day.

You cann’t consider simply how much time I had spent for this info!

Thank you!

Great article. I am facing many of these issues

as well..

Thanks for your personal marvelous posting! I actually enjoyed reading it, you could be a great author.

I will make certain to bookmark your blog and will eventually

come back from now on. I want to encourage yourself

to continue your great job, have a nice holiday weekend!

Hey, what a brilliant blog post I have actually encountered and thought me I have been locating for this similar kind of article for past a week as well as hardly encountered this. Thank you quite and I will try to find even more posts from you.

Great Article it’s innovative and really helpful keep us posted with new updates. its was really useful. thanks a whole lot.

thank you for sharing interesting things in this post, I hope I can see more of your work through other posts.

I was intrigued accepting that you at whatever point imagined of changing the plan of your site? Its very much made I genuinely like what you’ve got to say. However, no doubt you might somewhat more in the technique for material at some point so individuals could get along with it better.

Looking at this article, I miss the time when I didn’t wear a mask. totosite Hopefully this corona will end soon. My blog is a blog that mainly posts pictures of daily life before Corona and landscapes at that time. If you want to remember that time again, please visit us.

Hello! I recently wish to offer a massive thumbs up to the great information you have here with this post. We are returning to your blog for much more soon.

RSD https://ja.realsexdoll.com