|

| Mechanical Properties of Engineering Metals |

The mechanical properties of engineering materials have great importance in the design of machines, tool design, and structures. Engineering materials are used in every aspect of the area and hence it is important to study their mechanical properties.

Table of Contents

Mechanical Properties of Engineering Materials

The important mechanical properties of engineering materials are

- Strength

- Elasticity

- Stiffness

- Plasticity

- Ductility

- Malleability

- Toughness

- Hardness

- Brittleness

- Formability

- Castability

- Weldability.

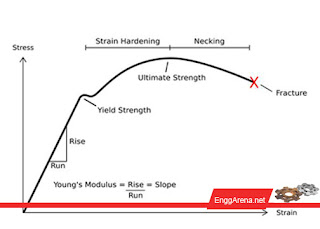

With the help of the stress-strain diagram, these properties can be well understood. A few important mechanical properties are discussed below :

Strength

Strength is defined as the ability of the material to resist the externally applied forces with breakdown or yielding. The internal resistance offered by a material to an externally applied force is called stress.

The capacity of bearing the load by metal and to withstand destruction under the action of external load is known as Strength.

The stronger the material, the greater the load it can withstand. This property of material, therefore, determines the ability to withstand stress without failure. Strength varies according to the type of loading. It is always possible to access tensile, compressive, shearing, and torsional strength.

The max stress that any material can withstand before destruction is called ultimate strength.

Elasticity

Elasticity is the property of a material to regain its original shape after deformation when the external forces are removed.

It can also be referred to as the power of the material to come back to its original position after deformation when stress or load is removed. It is also known as the tensile property of the material.

Stiffness

Stiffness is the ability of the material to resist deformation under the stress. The resistance of a material to the elastic deformation of deflection is called stiffness or rigidity.

A material that suffers very low or slight deformation under load, has high stiffness. For instance, suspended beams of steel and aluminum may both be strong enough to carry the required load but aluminum beams will sag or deflect further.

This means the steel beam is more rigid than the aluminum beam.

Plasticity

Plasticity is the mechanical property of the material which retains the deformation produced under the load permanently.

This property of the material is required in forging, in stamping images on coins, and in ornamental work. It is the ability or tendency of the material to undergo some degree of permanent deformation without its rupture or failure.

Plastic deformation takes place only after the elastic range of the material has been exceeded. Such property of a material is important in forging, stamping, shaping, extruding, and many other hot and cold working processes.

This property generally increases with an increase in its temperature.

Ductility

Ductility is termed as the property of the material enabling it to be drawn into the wire with the application of tensile load. Ductile material must be strong and plastic.

The ductility is usually measured by the terms, percentage elongation and percent reduction in the area which is often used as empirical measures of ductility.

Malleability

Malleability is the ability of the material to be flattened it into thin sheets under the application of heavy forces without cracking by the hot or cold working process.

It is a special case of ductility which permits material to be rolled or hammered into thin sheets. A malleable material should be plastic but it is not essential to be strong.

Hardness

Hardness is the ability of the metal to cut another metal.

A harder metal can always cut or put an impression on the softer materials by virtue of its hardness. It is a very important property of metals and has high a wide variety of meanings.

It embraces many different properties such as resistance to wear, scratching, deformation and machinability.

Brittleness

Brittleness is the property of the material exactly opposite to ductility. It is the property of the breaking of material with little permanent distortion.

The materials having less than 5% elongation under loading behavior are said to be brittle material. Brittle materials when subjected to tensile load snap off without giving any sensible elongation.

Formability

Formability is the property of the metals which denotes ease in its forming into various shapes and sizes.

The different factors that affect formability are the crystal structure of the metal, the grain size of metal, hot and cold metalworking, an alloying element present in its parent metal.

Metals with small grain sizes are suitable for shallow forming while metals with size are suitable for heavy forming. Hot-working increases formability.

Low carbon steel possesses good formability.

Castability

Castability is defined as the property of the metal which indicates the ease with it can be cast into different shapes and sizes.

Weldability

Weldability is the property of the metal which indicates the two similar or dissimilar metals are joined together by fusion with or without application of pressure and with or without the use of filler metal efficiently.

Metals having weldability is descending order are iron, steel, cast steel, and stainless steel.

Way cool! Some very valid points! I appreciate you penning this

post and the rest of the site is also really good.