Table of Contents

What is Mean by Hydraulic Press?

A hydraulic press is a machine press that uses a hydraulic cylinder to generate a compressive force.

Hydraulic systems use Pascal’s law which states that

The external static pressure applied on a confined liquid is distributed or transmitted evenly throughout the liquid in all directions.

In simple terms, we can say that pressure applied to an enclosed fluid will be transmitted without a change in magnitude to every point of the fluid. The pressure at any point in the fluid is equal in all directions.

Pascal’s law is given by the formula, F=P*A

where,

F= force applied,

P= Pressure transmitted

A= Cross-sectional area

In hydraulic press, the same principle is used for lifting heavy weight by the application of much smaller force.

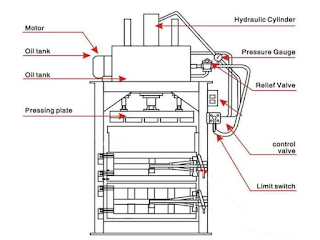

Main components of Hydraulic Press System

The main component of the hydraulic press are

- Hose

- Hydraulic Motor

- Reservoir Tank

- Direction Control Valve

- Pressure relief valve

- Pressure gauge

- Limit switch

- Hydraulic cylinder

- Pressing plate.

| Basic Components of Hydraulic Press System |

Hose

Hydraulic hose is used to convey the hydraulic fluid to or between the hydraulic components.

Hydraulic motor

A hydraulic motor is used to pump the hydraulic fluid in the system. The motor is usually equipped with a pump for pumping purposes.

Read more: Different types of Hydraulic Pumps.

Reservoir tank

Hydraulic oil is stored in the reservoir tank.

Direction control valve

Direction control valves (DCVs) are used to control the direction of the actuator/cylinder. Generally, a manually controlled DCV is used in the hydraulic press.

Read more: Direction Control Valves and their types

Pressure relief valve

It is used to control the pressure in the system.

Limit Switch

It is used to control the position of the piston of the cylinder. It prevents the cylinder to travel post a predetermined point.

Hydraulic cylinder

This is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke.

Read more: Different types of Hydraulic Cylinders.

Circuit Diagram and Simulation of a Hydraulic Press

Working Principle of Hydraulic Press

|

| Working Principle of Hydraulic Press |

The working principle of hydraulic press is based on Pascal’s law which states that the intensity of pressure in a static fluid is transmitted equally in all directions.

A hydraulic press consists of two different cylinders of two different diameters.

One cylinder is of smaller diameter that contains a plunger and another cylinder is of larger diameter that contains Ram.

These two cylinders are connected through a pipe/hose which contains hydraulic fluid through which pressure is transmitted.

When a smaller force F is applied on the plunger, pressure is produced in the liquid.

As per Pascal’s law, this pressure is transmitted equally in all directions and act on the Ram. Thus, the Ram is pushed forward and heavier objects can be easily lifted.

Applications of Hydraulic press

- Manufacturing Industry

Hydraulic presses are widely used for automotive folding and forming applications. Brake pads, sealing components, insert molding, truck bed liners, electrical connectors and insulators, fuel delivery parts, etc. are the vehicle parts manufactured using hydraulic presses.

- Manufacturing Electrical Parts

These are widely used to assemble the housings and switches used in switching stations. Thermostats are also manufactured with the help of a hydraulic press.

- Military Applications

Presses are used in most of the air force bases. They are commonly used for loading the shells.

- Building Aircrafts

In the Aerospace industry, they are used for metal forming and machinery fabricating processes. Windshield wiper blades, gear assemblies, airplane body panels, and wings are built using hydraulic presses.

- Metal forming operations

- Deep drawing operations

- Punching operations

- Blanking operations

- Molding operations

- Clinching operations

- Forging operations

It was very interesting to know that the hydraulic press equipment is used in building military aircrafts as it can form metals. The fact that this equipment is used in various important industries in the world fascinates me. I can only imagine every company out there that involves industrial and manufacturing would want a good custom hydraulic press manufacturer for their business.

Its very intresting,thank you very much.

Great

Very nice blog and articles. I am really very happy to visit your blog.

I was searching for a blogpost like this. This post is a complete and comprehensive effort.

Thanks

Artical is very informative.

I was searching for a blog post like this. This post is a complete and comprehensive effort.

I was searching for a blog post like this. This post is a complete and comprehensive effort.

This post is wonderful and thanks for sharing this useful post.

Great Info, Thanks For Sharing , keep it up we are here to learn more

Topaz Sharpen AI Crack For Serial Key is a powerful tool that sharpens and enhances the original details of your images using the most advanced AI technology.

I am a fan of technology, education, and writing. I’m also interested in programming.

IDM Crack is an application that enables fast download speeds from the Internet. As one of the leading download managers available today, Download Manager stands out with various features and benefits that make it indispensable. Anyone who downloads frequently should make Download Manager part of their routine download regimen.

There are several ways to check your Xbox Series X graphics card. The first step is to check the settings. Go to the home screen and select the system tile to do this. Then select Settings and click on the System Information tab. Here you can find information about the console, including graphics cards.

Thanks for sharing this with us, its very informative and productive, hope you will share more in future