Bearings are used to reduce friction when there is a relative motion between two parts like shaft and housing. There are two major groups of bearings, sliding contact bearing and rolling contact bearing. In this topic, we will discuss rolling contact bearing.

Table of Contents

What are Bearings?

Bearing is a mechanical element that permits relative motion between two parts, such as the shaft and the housing, with minimum friction.

A rolling contact bearing is also known as an antifriction bearing. However, this is misnaming because there is always friction between the rolling element and the inner and outer cages.

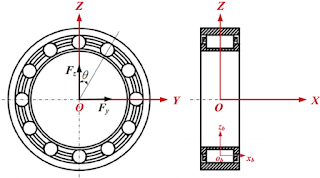

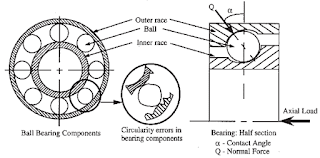

A rolling contact bearing consists of four parts – inner and outer races, a rolling element such as ball, roller, or needle, and a cage that holds the rolling element together and are equispaced around the periphery of the shaft.

Types of Bearings

Depending upon the type of load, bearings are classified as Radial bearings and Thrust bearings. However, there is no clear distinction between these two bearings types. Certain types of radial bearings can take thrust load, while certain thrust bearings can take the radial load.

Depending upon the type of rolling element, bearings are classified as

- Deep groove Ball-bearing

- Cylindrical roller bearing

- Angular Contact bearing

- Self-aligning bearing

- Taper roller bearing

- Thrust ball bearing.

Let us see the types of rolling contact bearings, which are frequently used.

Deep groove ball bearing

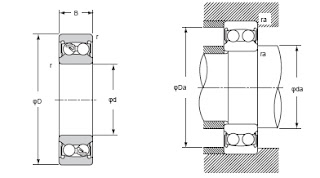

Deep groove ball bearings are the most frequently used ball bearings. Deep groove ball bearings are found in almost all types of products in general mechanical engineering.

In this type of bearing, the radius of the ball is slightly less than the radii of curvature of the grooves in the races. Therefore, the balls and the races may roll freely without any sliding.

|

| Nomenclature of Deep groove ball bearing |

Advantages of Deep groove ball bearings

- Deep groove ball bearings take the load in radial as well as the axial direction.

- Due to the relatively large size of the balls, deep groove ball bearing has a high load-carrying capacity.

- Due to point contact between the balls and races, frictional loss and resultant temperature rise are less in this bearing. The maximum permissible speed of the shaft depends upon the temperature rise of the bearing.

- Deep groove ball bearings give excellent performance in high-speed applications.

- Due to point contact, these bearings are less noisy.

- The deep groove ball bearing is available with a bore diameter from a few millimeters to 400 millimeters.

Disadvantages of Deep groove ball bearings

- The deep groove ball bearing is not self-aligning. Accurate alignment between the axes of the shaft and the housing bore is required.

- These bearings have poor rigidity compared to roller bearings. This is due to point contact compared with the line contact of the roller bearing.

- It is not suitable for a machine tool spindle where rigidity is an important consideration.

Cylindrical roller bearing

When maximum load-carrying capacity is required in a given space, the point contact in a ball bearing is replaced by line contact of the roller bearing. Cylindrical roller bearing consists of relatively short rollers that are positioned and guided by the cage.

|

| Cylindrical roller bearing |

Advantages of Cylindrical roller bearing

- Due to line contact between rollers and races, the radial load-carrying capacity of the cylindrical roller bearing is very high.

- The cylindrical roller bearing is more rigid than a ball bearing.

- The coefficient of friction is low and frictional loss is less in high-speed applications.

Disadvantages of Cylindrical roller bearing

- In general, cylindrical roller bearing cannot take a thrust load.

- The cylindrical roller bearing is not self-aligning. It cannot tolerate misalignment. It needs precise alignment between the axes of the shaft and the bore of the housing.

- Cylindrical roller bearing generates more noise.

Angular contact bearing

In angular contact bearing, the grooves in the inner race and outer races are so shaped that the line of reaction at the contact between balls and races makes an angle with the axis of the bearing. This reaction has two components, radial and axial.

Therefore, angular contact bearing can take the thrust loads and radial loads. Angular contact bearings are often used in pairs, either side by side or at the opposite ends of the shaft, in order to take the thrust load in both directions. These bearings are assembled with a specific magnitude of pre-load.

|

| Angular contact bearing |

Advantages of Angular contact bearing

- Angular contact bearing can take both radial and thrust loads.

- In angular contact bearing, one side of the groove in the outer race is cut away to permit the insertion of more number of balls than that of the deep groove ball bearing. This permits the bearing to carry relatively large axial and radial loads.

- The load-carrying capacity of angular contact bearing is more than a deep groove ball bearing.

Disadvantages of Angular contact bearing

- Two bearings are required to take thrust load in both directions.

- Angular contact bearing must be mounted without axial play.

- Angular contact bearings require initial preloading.

Self-aligning bearings

There are two types of self-aligning rolling contact bearings, self-aligning ball bearing and spherical roller bearing.

The self-aligning ball bearing consists of two rows of balls, which roll on a common spherical surface in the outer race.

In this case, the assembly of the shaft, the inner race, and the balls with a cage can freely roll and adjust itself to the angular misalignment of the shaft.

There is a similar arrangement in a spherical roller bearing, where balls are replaced by two rows of spherical rollers, which run on a common spherical surface in the outer race.

|

| Self-aligning bearing |

Compared with self-aligning ball bearing, spherical roller bearing can carry relatively high radial and thrust loads. Both types of self-aligning bearing permit minor angular misalignment of the shaft relative to the housing.

They are therefore particularly suitable for applications where misalignment can arise due to errors in mounting or due to deflection of the shaft. They are used in agricultural machinery, ventilators, and railway axle boxes.

Taper roller bearings

The taper roller bearing consists of rolling elements in the form of a frustum of a cone. They are arranged in such a way that the axes of individual rolling elements intersect in a common apex point on the axis of the bearing.

In kinematics analysis, this is an essential requirement for pure rolling motion between conical surfaces.

In taper roller bearing, the line of resultant reaction through the rolling elements makes an angle with the axis of the bearing. Therefore taper roller bearing can carry both radial and axial loads.

In fact, the presence of either component results in the other, acting on the bearing. In other words, a taper roller bearing subjected to pure radial load induces thrust component and vice versa. Therefore, taper roller bearings are always used in pairs to balance the thrust component.

Taper roller bearing has separable construction. The outer ring is called ‘cup’ and the inner ring is called ‘cone’. The cup is separable from the remaining assembly of the bearing elements including the rollers, cage, and cone.

Taper roller bearing has separable construction. The outer ring is called ‘cup’ and the inner ring is called ‘cone’. The cup is separable from the remaining assembly of the bearing elements including the rollers, cage, and cone.

Advantages of Taper roller bearing

- Taper roller bearing can take heavy radial and thrust loads.

- Taper roller bearing has more rigidity

- Taper roller bearing can be easily assembled and disassembled due to separable parts.

Disadvantages of Taper roller bearing

- It is necessary to use two taper roller bearings on the shaft to balance the axial force.

- It is necessary to adjust the axial position of the bearing with preload. This is essential to coincide the apex of the cone with the common apex of the rolling elements.

- Taper roller bearing cannot tolerate misalignment between the axes of the shaft and the housing bore

- They are costly.

Taper roller bearings are used for cars and trucks, propeller shafts, and differentials, railroad axle boxes, and large size bearings in rolling mills.

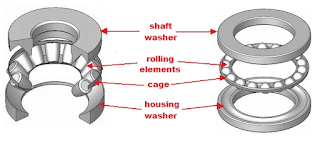

Thrust ball bearing

Thrust ball bearing consists of a row of balls running between two rings i.e. shaft ring and housing ring.

Thrust ball bearing carries thrust load in only one direction and cannot carry any radial load. The use of a large number of balls results in high thrust load carrying capacity in smaller spaces. This is the major advantage of the thrust ball bearing.

Advantages of Thrust Ball Bearing

- It carries the load in only one direction.

- High thrust carrying capacity in smaller spaces.

Disadvantages of Thrust ball bearing

- Thrust ball bearing cannot take the radial load.

- It is not self-aligning and cannot tolerate misalignment.

- Their performance is satisfactory at low and medium speeds. At higher speeds, these bearings give poor performance because the balls are subjected to centrifugal forces and gyroscopic couple.

- Thrust ball bearing does not operate as well on horizontal shafts as they do on vertical shafts.

- Thrust ball bearings require continuous pressure applied by springs to hold the ring together.

Thrust ball bearings are used where heavy thrust loads are to be carried, for example, worm gearboxes and crane hooks.

Materials for Rolling Contact Bearings

There are specific materials for the parts of rolling contact bearings. They are as follows:

- The balls and the inner and outer races are made of high carbon chromium steel (SAE 52100 or AISI 5210). It contains 1% carbon and 1.5% chromium. The balls and races are through-hardened to obtain a minimum hardness of 58 Rockwell C.

- The cages are made from stampings of low-carbon steel.

- The rollers are made of case-hardened steel (AISI 3310, 4620, or 8620). They are case carburized to obtain a surface hardness of 58 Rockwell C.

4 thoughts on “6 Types of Bearings | Rolling Contact Bearing”